Malaysia’s biodiesel production for 2019 is forecast to hit 1.56 billion litres, having launched the B10 blend (10% palm biodiesel + 90% petrol diesel) last December to spur market demand. Malaysia is riding on its existing capacity being the second largest palm oil producer to support the rising global demand for biofuels of vegetable origins.

Palm biodiesel, a type of liquid bioenergy fuel (biofuel), is gaining prominence as a renewable energy that can either be used together with petrol diesel in any proportion or as a full substitute on diesel engines without modification, in transport and industrial applications.

It is one of the important economic and revenue growth drivers that adds value to palm oil’s downstream industry with a global market access to tap into as the Malaysian government is diligently exploring new markets in Africa, the Middle East and Central Asia, in addition to expanding the traditional markets led by India, the EU, China and Pakistan.

Chemically, palmitic acid (C16) and stearic acid (C18) are the major components (saturated fatty acids) used for producing palm biodiesel. And of course, driven by innovative technologies, oil palm is now a zero-waste crop where wastes from palm oil industry are used as the feedstocks (raw materials) for biodiesel production.

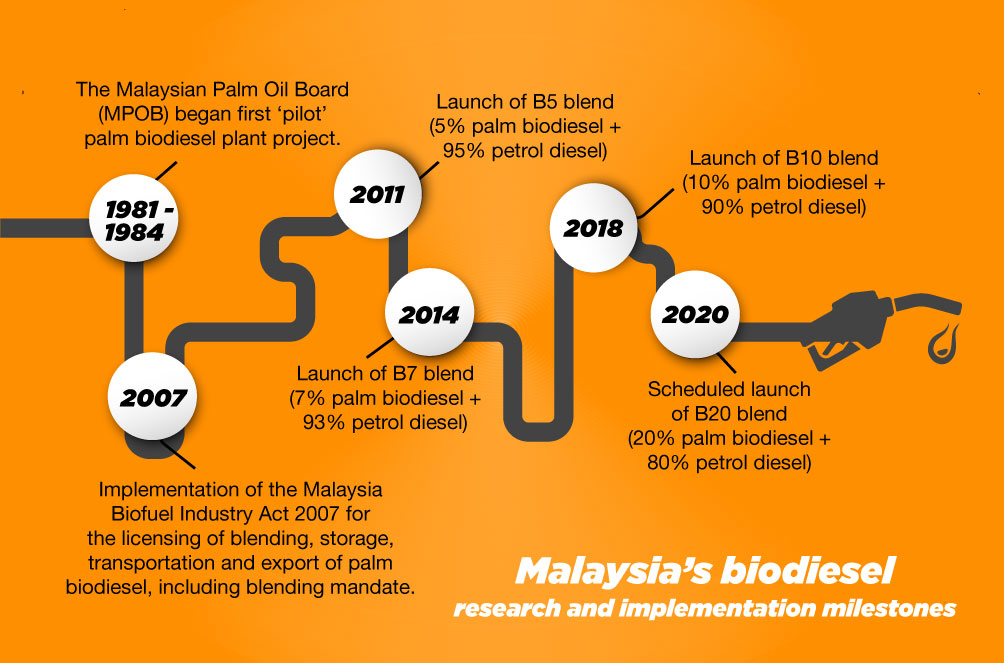

Malaysia has been pioneering the research and development of palm biofuel since the early 1980s, focusing on the energy and transportation ecosystem. The country is planning to launch the B20 blend (20% palm biodiesel + 80% petrol diesel) next year (2020).

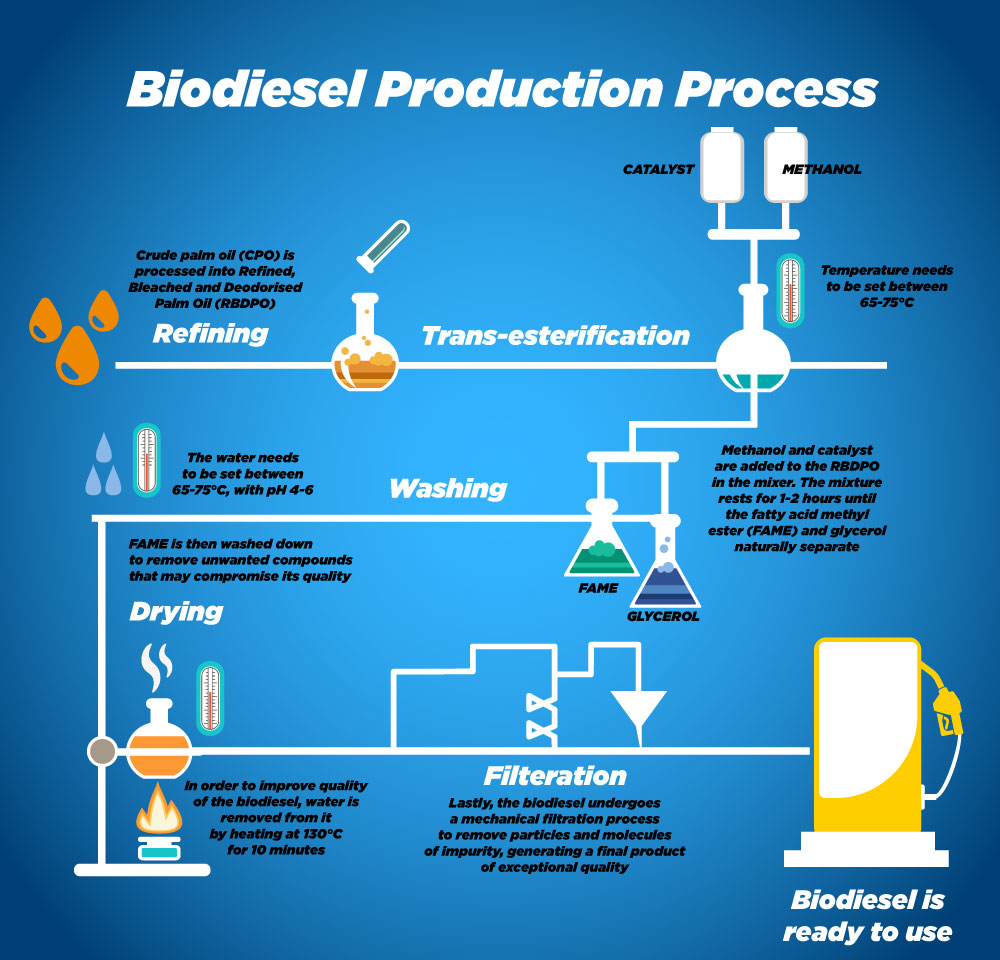

The preparation and production of biodiesel may come through one of the following methods: trans-esterification (the most common method), blending (dilution), microemulsification, and pyrolysis (thermal cracking). Take a good look at the following diagram to help your understanding.

NST reports that biodiesel is technically more superior to normal diesel. It has a higher lubricity, which means lower wear-and-tear for the engine. Biodiesel burns more thoroughly than normal diesel, due to the fact that it contains oxygen. This results in the blend having a high cetane number, indicator of ease of combustion.

Industry expert Mark Dehner explains that the higher the cetane number, the faster the fuel will ignite and the more completely it will burn, meaning the engine experiences greater performance and produces fewer harmful emissions, as a result.

Other advantages of palm biodiesel are explained here.